Manifold Primer

Manifold Primer

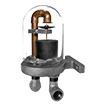

The Manifold Primer, aka Water Trap, (MP) is a device positioned between a water pump being primed and a source of vacuum pulling the water. It is designed to stop water flow when water reaches it. As a manifold primer, it is used when the vacuum source is the intake manifold of a multiple-cylinder gasoline or LP gas engine, or brake booster of a vehicle. As a water trap, it is used when the vacuum source is a vacuum pump. The manifold primer/water trap utilizes a mechanical float valve that stops airflow as water enters the unit, thus “trapping” and preventing the water from continuing past it.

Manifold Primer Uses

LP or Gasoline Engine Intake. Manifold primers like our proprietary MP1000 are used to initiate suction when the vacuum source is the intake manifold of a multiple-cylinder gasoline or LP gas engine, or brake booster of a vehicle.

Water Pump Trap for Vacuum Pumps. As a water trap it is used when the vacuum source is a vacuum pump. The manifold primer/water trap utilizes a mechanical float valve that stops airflow as water enters the unit, thus “trapping” and preventing the water from continuing past it.

Other Manifold Primer Names: Although the primary name for this type of suction device is manifold primer, there are other nicknames and synonyms to describe them in different industries including: manifold primer water pump, vaccum manifold primer, manifold vacuum primer, irrigation manifold pump, water manifold pump.

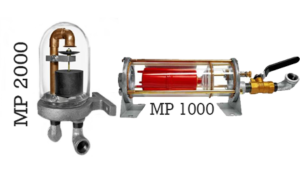

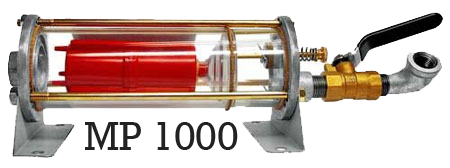

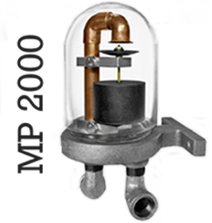

Difference Between MP1000 and MP2000

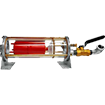

- MP1000 – Has 3/8 NPT flow ports, IN at bottom and OUT at top. Mounting requires four 1/4″ bolts or screws. Water drains from the unit through the priming line.

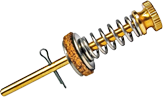

- MP2000 – Has 1/2 NPT IN and OUT flow ports on the bottom. Mounting requires two 1/4″ bolts or screws. Water drains from the unit through an umbrella valve on the bottom.

-

INSTALLATION

- Mount the unit in position so that the float mechanism moves vertically and is at an elevation above the pump priming port.

- Use noncollapsible hose to connect the unit OUT port to the vacuum source, for example a tee fitting spliced into the vacuum line.

- Use noncollapsible hose to connect the unit IN port to the pump priming port, with the provided ball valve in between.

-

OPERATION

- Close the priming line ball valve.

- Close the pump discharge valve to prevent air being drawn through the discharge.

- Start the vacuum source.

- Open the priming line ball valve.

- When water enters unit, close priming line ball valve. (Water entering unit indicates pump is primed.)

- Start the pump and open the pump discharge valve.

- Stop the vacuum source then allow the water to drain from the unit

*NOTE: If water does not flow from discharge, turn your pump OFF and repeat steps 2 through 5. When pump is discharging properly the priming line may be disconnected from primer and the engine providing vacuum turned OFF.

-

MAINTENANCE

-

- Chamber housing should be kept clean in order to observe the float valve. *If necessary, remove the unit and flush with water or a mild soap solution.

- Use only soap and water to clean plastic parts. *Do not use any harsh cleanser or chemicals to clean the unit.

- Do not tighten tie bolts or plastic dome more than necessary to provide seal.

- Keep the priming line ball valve closed when manifold primer/water trap not in use.

-

-

MP1000 & MP2000 Manifold Primer – Parts